Training

-

Training is essential part of proper operations. Better operations, maintenance will lead to “Safe-n-Healthy” operations of Thermic fluid system.

-

Factory law in some states insist to keep Tf heater under trained manpower.

-

Eximious has devised novel training programs to train people. The training can be imparted to various levels such as operators, engineers.

-

Basic training on Do’s and Don’ts, Safeties, Oil parameters etc can be arranged.

Training

-

Training is essential part of proper operations. Better operations, maintenance will lead to “Safe-n-Healthy” operations of Thermic fluid system.

-

Factory law in some states insist to keep Tf heater under trained manpower.

-

Eximious has devised novel training programs to train people. The training can be imparted to various levels such as operators, engineers.

-

Basic training on Do’s and Don’ts, Safeties, Oil parameters etc can be arranged.

Training

-

Training is essential part of proper operations. Better operations, maintenance will lead to “Safe-n-Healthy” operations of Thermic fluid system.

-

Factory law in some states insist to keep Tf heater under trained manpower.

-

Eximious has devised novel training programs to train people. The training can be imparted to various levels such as operators, engineers.

-

Basic training on Do’s and Don’ts, Safeties, Oil parameters etc can be arranged.

Training

-

Training is essential part of proper operations. Better operations, maintenance will lead to “Safe-n-Healthy” operations of Thermic fluid system.

-

Factory law in some states insist to keep Tf heater under trained manpower.

-

Eximious has devised novel training programs to train people. The training can be imparted to various levels such as operators, engineers.

-

Basic training on Do’s and Don’ts, Safeties, Oil parameters etc can be arranged.

Training

-

Training is essential part of proper operations. Better operations, maintenance will lead to “Safe-n-Healthy” operations of Thermic fluid system.

-

Factory law in some states insist to keep Tf heater under trained manpower.

-

Eximious has devised novel training programs to train people. The training can be imparted to various levels such as operators, engineers.

-

Basic training on Do’s and Don’ts, Safeties, Oil parameters etc can be arranged.

Training

-

Training is essential part of proper operations. Better operations, maintenance will lead to “Safe-n-Healthy” operations of Thermic fluid system.

-

Factory law in some states insist to keep Tf heater under trained manpower.

-

Eximious has devised novel training programs to train people. The training can be imparted to various levels such as operators, engineers.

-

Basic training on Do’s and Don’ts, Safeties, Oil parameters etc can be arranged.

Training

-

Training is essential part of proper operations. Better operations, maintenance will lead to “Safe-n-Healthy” operations of Thermic fluid system.

-

Factory law in some states insist to keep Tf heater under trained manpower.

-

Eximious has devised novel training programs to train people. The training can be imparted to various levels such as operators, engineers.

-

Basic training on Do’s and Don’ts, Safeties, Oil parameters etc can be arranged.

Training

-

Training is essential part of proper operations. Better operations, maintenance will lead to “Safe-n-Healthy” operations of Thermic fluid system.

-

Factory law in some states insist to keep Tf heater under trained manpower.

-

Eximious has devised novel training programs to train people. The training can be imparted to various levels such as operators, engineers.

-

Basic training on Do’s and Don’ts, Safeties, Oil parameters etc can be arranged.

Training

-

Training is essential part of proper operations. Better operations, maintenance will lead to “Safe-n-Healthy” operations of Thermic fluid system.

-

Factory law in some states insist to keep Tf heater under trained manpower.

-

Eximious has devised novel training programs to train people. The training can be imparted to various levels such as operators, engineers.

-

Basic training on Do’s and Don’ts, Safeties, Oil parameters etc can be arranged.

Training

-

Training is essential part of proper operations. Better operations, maintenance will lead to “Safe-n-Healthy” operations of Thermic fluid system.

-

Factory law in some states insist to keep Tf heater under trained manpower.

-

Eximious has devised novel training programs to train people. The training can be imparted to various levels such as operators, engineers.

-

Basic training on Do’s and Don’ts, Safeties, Oil parameters etc can be arranged.

Thermic Fluid System

We Understand Thermic Fluid Better !!!

Eximious Ventures Pvt. Ltd.

ISO 9001 - 14001 Certified

(+91) 8080 365 24 7

info@evpl.co.in

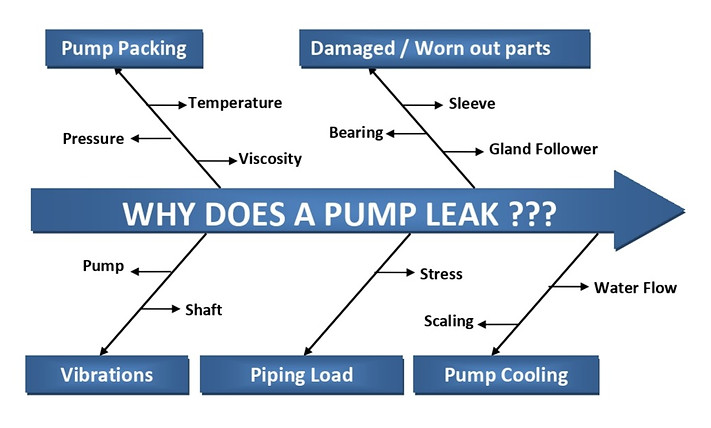

Pump Packing

Why thermic fluid pump leaks?

-

Worn out parts allow leak. Worn out bearing create vibrations and imbalance. Worn out sleeve gives passage to thermic fluid. Worn gland follower doesn’t hold glands properly.

-

Thermic fluid pump needs proper water-cooling. In case of scaled casing or low flow of cooling media, adequate cooling is not provided. This results in gland packing losing life.

-

Vibrations, misalignment and stresses create uneven load and lead to leakage.

-

Pump packing unsuitable for duty conditions such as, high temperature,

high pressure or changing viscosity of the thermic fluid, with rise in temperature,

will lead to leakage.

As per PCRA, 60 drops/min leak corresponds to 1.5 litre of oil leakage per shift or 4.5 litre of oil per day. This corresponds to about ₹550 /day of oil wastage (Assumed TF rate ₹125 /litre). A 10 day expenditure on an oil leak would be approx. ₹5500.

These costs are proportional to the quantities of the leaked oil.

Macstar Hotpack controls leak to 2 drops / min.